In-space manufacturing could sound like science fiction but it surely’s occurring already, albeit on a really small scale. It is a fledgling market that analysts and several other startups are projecting will take off.

“In case you have a look at pharma, semiconductors, health and beauty merchandise and doubtlessly meals within the sense of like new crops, we estimated the market to be above $10 billion sooner or later in 2030, relying on the velocity of maturation,” mentioned Ilan Rozenkopf, a associate at McKinsey.

House presents a singular surroundings for analysis and growth as a result of its larger ranges of radiation, microgravity and close to vacuumless state permits corporations to give you new manufacturing strategies or supplies that aren’t doable on Earth.

The observe is just not completely new. The Worldwide House Station has hosted a number of experiments from lecturers, authorities businesses and industrial prospects for issues resembling rising human tissue, making purer semiconductors and growing new or higher medication. Within the 2024 fiscal-year finances, President Joe Biden even put aside $5 million for NASA to pursue cancer-related analysis on the ISS.

However entry to the ISS has all the time been aggressive and curiosity continues to develop. Now, a number of area startups see a chance to fulfill in-space manufacturing demand utilizing compact area factories. One firm is Varda House Industries in Southern California. Varda’s mission is to assist pharmaceutical corporations enhance their medication or give you new drug therapies by profiting from the distinctive properties of area, after which return these supplies again to Earth.

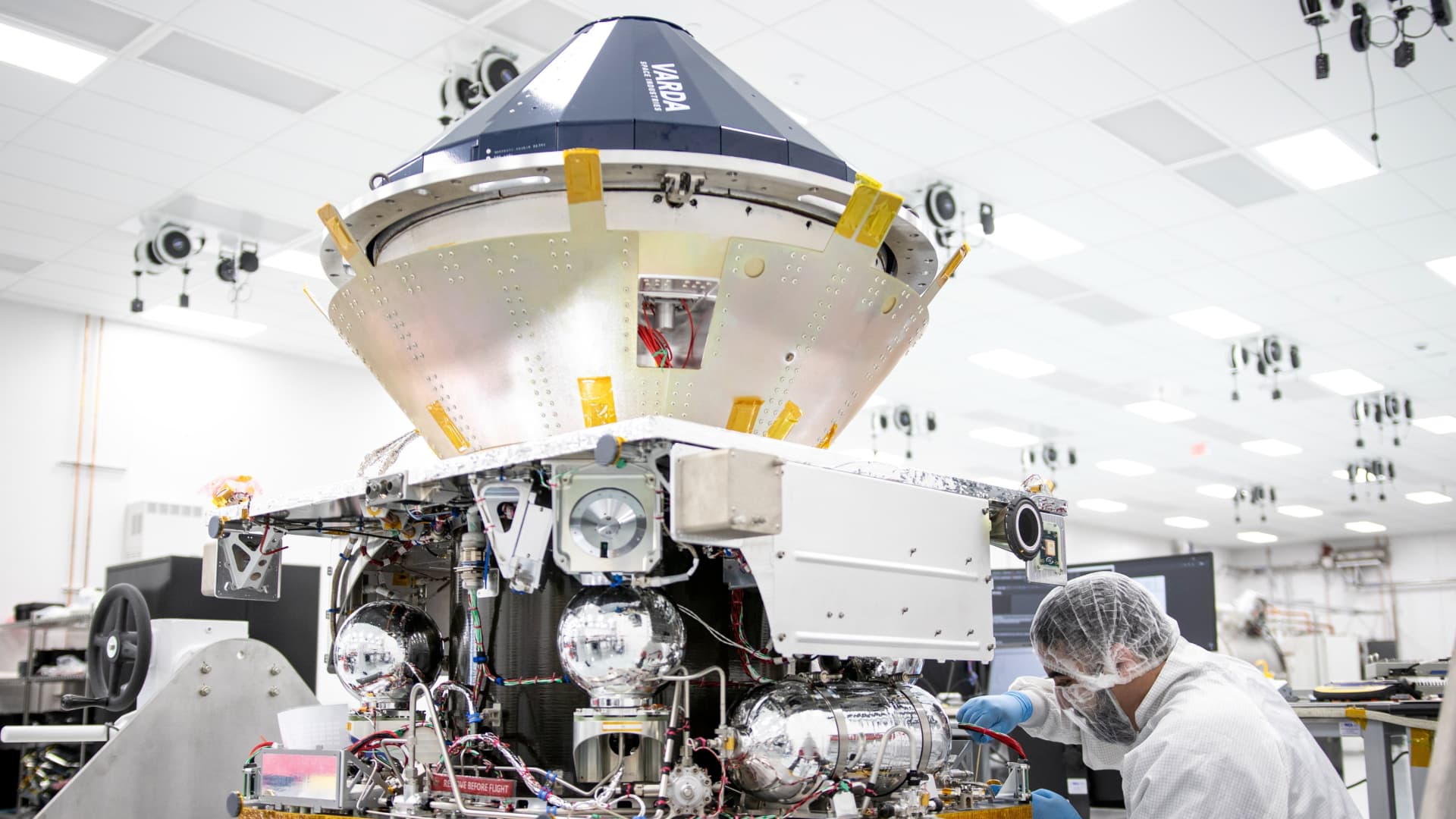

Varda House Industries’ first pharmaceutical manufacturing satellite tv for pc and reentry automobile hooked up to a Rocket Lab Photon bus.

Rocket Lab

Key to Varda’s enterprise proposition is a phenomenon often called protein crystallization.

This happens when super-saturated protein options are primarily evaporated to type a stable so scientists can research a protein’s construction. Understanding the crystal construction of a protein might help scientists get a greater concept of illness mechanisms, determine drug targets and optimize drug design. Assume medication which have much less unwanted effects, are more practical or can stand up to a larger array of situations resembling not needing to be refrigerated.

Years of analysis have proven that protein crystals grown in area are a lot larger high quality than these grown on Earth. The plan is to not make all the drug in outer area, simply what is called the first lively pharmaceutical ingredient, or the portion accountable for the therapeutic results of a drug.

“You are not going to see us making penicillin or ibuprofen or some of these very generic mass consumption targets, given the quantity of crystalline it’s essential create is much past our present capabilities,” mentioned Delian Asparouhov, co-founder and president of Varda House Industries. “However there’s a large set of medication that do billions and billions of {dollars} a 12 months of income that actively match inside the manufacturing measurement that we are able to do even on our present manufacturing facility.”

Asparouhov mentioned that within the U.S. in 2021 and 2022, of the lots of and thousands and thousands of doses of the Pfizer Covid vaccine administered, “the precise whole quantity of consumable major pharmaceutical ingredient of the particular crystalline mRNA, it successfully was lower than two milk gallon jugs.”

Throughout the Atlantic in Cardiff, Wales, House Forge is engaged on designing its personal in-space manufacturing unit to fabricate next-generation semiconductors. House Forge’s aim is to make semiconductor substrates utilizing supplies aside from silicon to fabricate extra environment friendly, larger performing chips.

“This subsequent technology of supplies goes to permit us to create an effectivity that we have by no means seen earlier than,” mentioned Andrew Parlock, managing director of House Forge’s U.S. operations. “We’re speaking about 10 to 100 X enchancment in semiconductor efficiency.”

A rendering of House Forge’s ForgeStar manufacturing satellite tv for pc.

House Forge

Identical to with prescribed drugs, the key sauce to reaching one of these efficiency enchancment in semiconductors lies in creating the proper crystals in area. A lot of these superior chips are necessary for industries resembling 5G and electrical autos. Much like Varda, House Forge plans to fabricate solely a part of the chips in area.

“As soon as we have created these crystals in area, we are able to deliver them again right down to the bottom and we are able to successfully replicate that progress on Earth,” mentioned Josh Western, CEO and co-founder of House Forge. “So we need not go to area numerous occasions to construct up fairly good scale working with our FAB companions and prospects on the bottom.”

To study extra about in-space manufacturing in addition to Varda and House Forge’s plans to make the observe a viable enterprise, watch the video.